The Orbiter™: Rotating Cleaning Tool

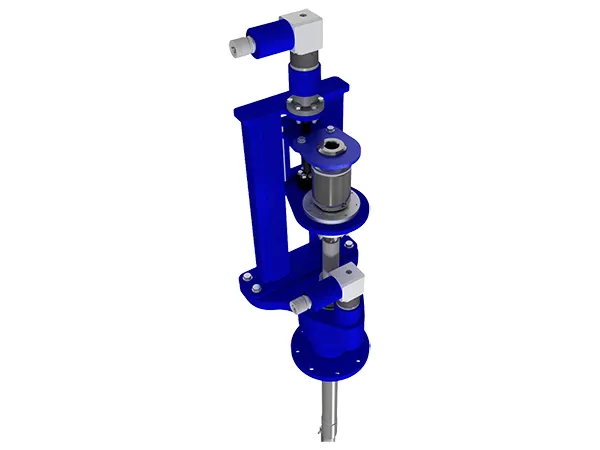

All-electric rotating cleaner for railcars, floating-roof tanks, and vessels. Mountable in any orientation – top, side, or inverted – for remote, high-performance industrial cleaning.

One tool. Two performance modes. Swap nozzles on The Orbiter™ to easily shift between high-flow and high-pressure cleaning.

Overview

Laminar Flow Plath

– Adjustable tilt up to 70°

– Real-time directional control

Rotational Movement

– Full 360° rotation for full coverage of railcars, floating-roof tanks, and vessels.

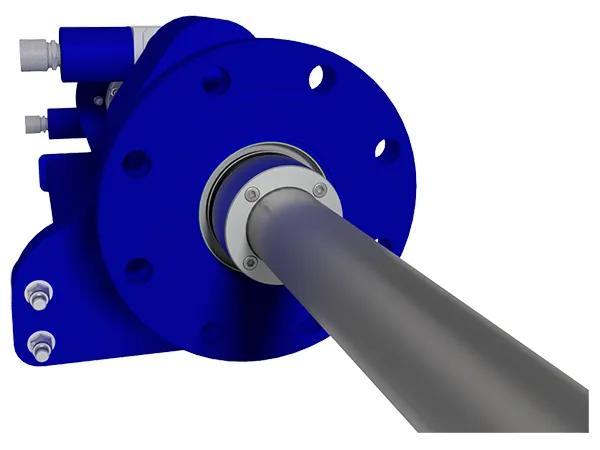

Flange Mount

– 4″ Class 150# flange

– Adapatable to larger flange sizes with adapter plates

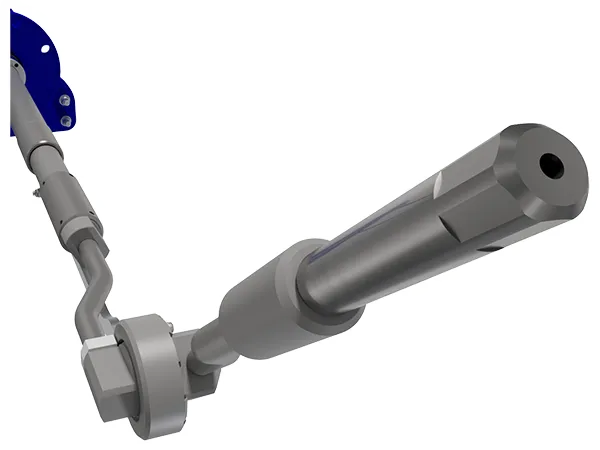

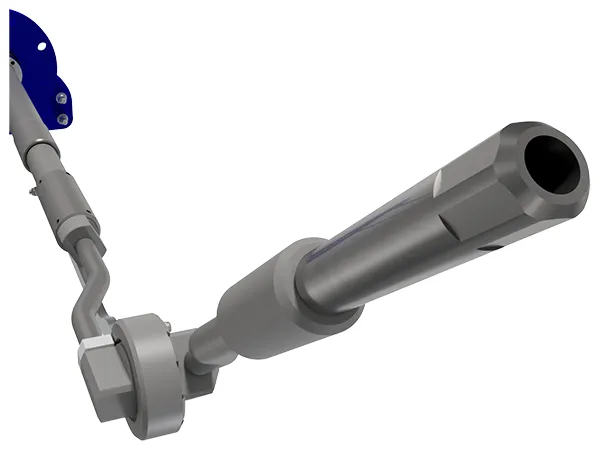

Quick-Change Nozzles

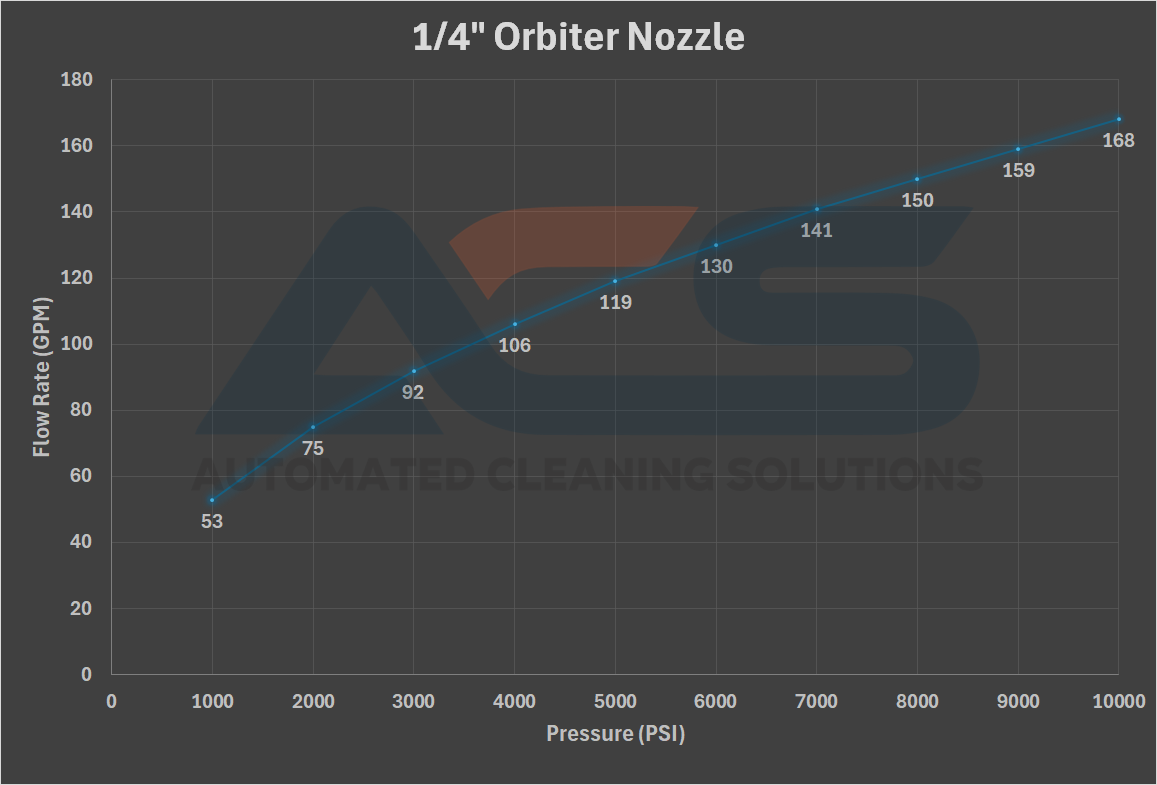

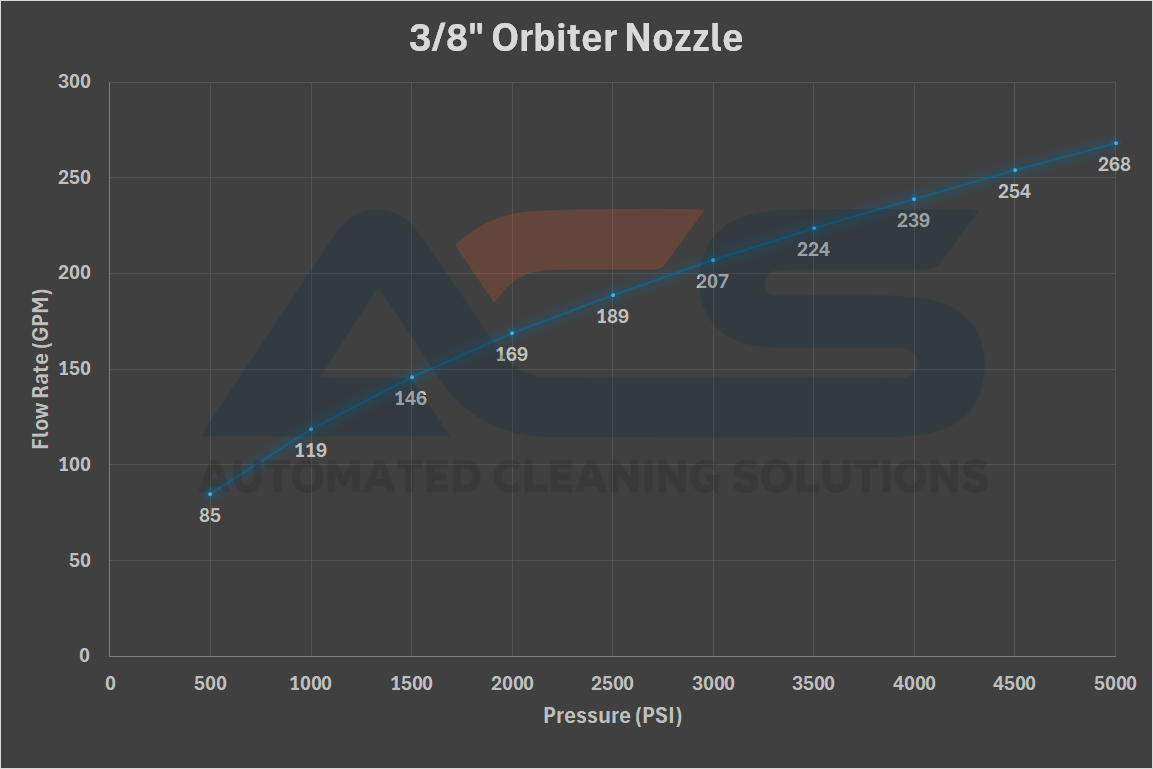

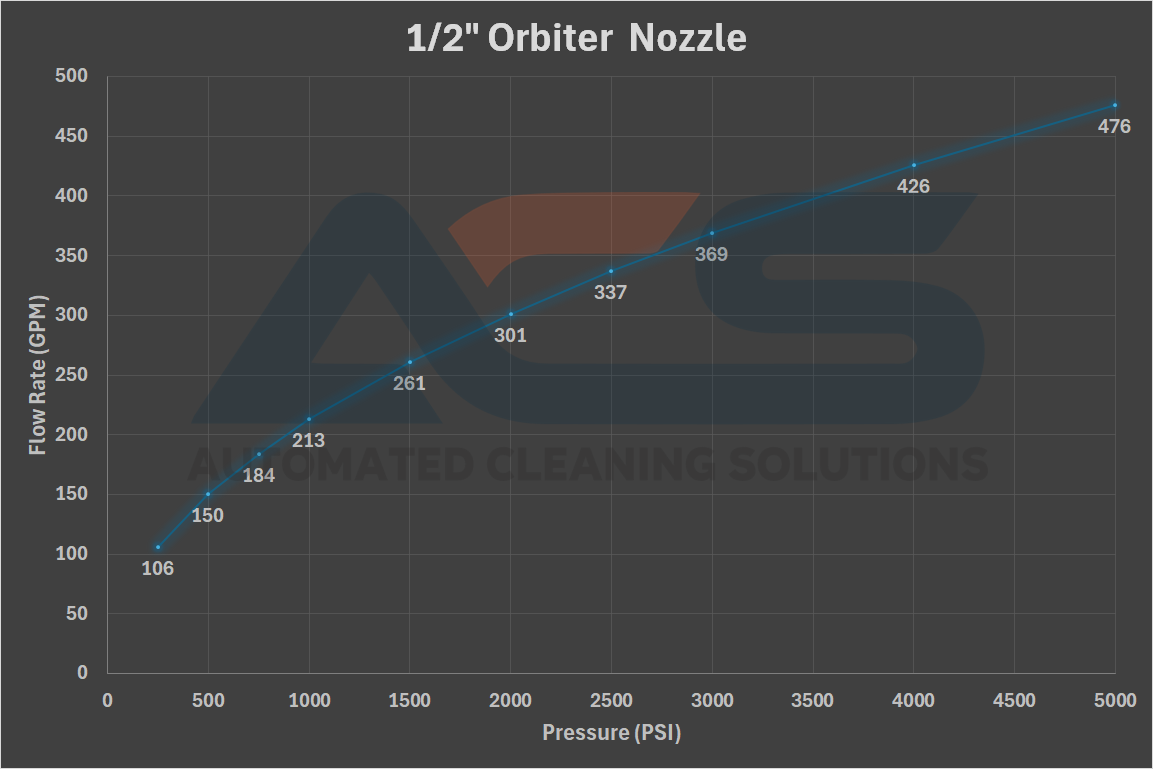

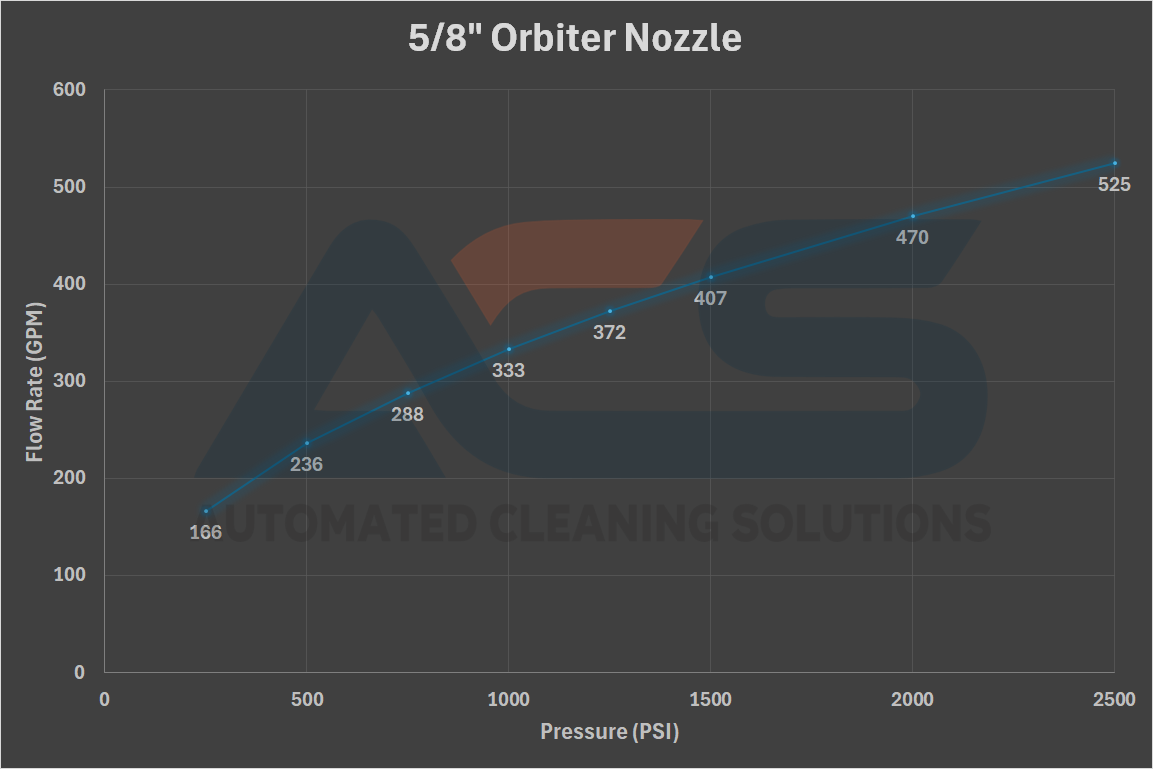

– ¼”, ⅜”, ½”, ⅝” nozzles for high-pressure

– 1″ nozzle for high-flow

Features & Benefits

All-Electric Performance

Powered by a standard 120~240 VAC electrical circuit. No hydraulics.

Instant, precise, lag-free motion.

Adjustable speed from 0.1°/s (ultra-slow) to 10°/s (ultra-fast)

No hydraulic motor or hoses required.

High Pressure Impact

Target hardened buildup with up to 10,000 psi of focused force for high-impact cleaning.

Breaks down heavy residue for faster washdown and slurry evacuation

Quick-change nozzles – ¼”, ⅜”, ½”, ⅝” – for the right impact every time

Operate at the pressure and flow you need to get the job done

High-Flow Mode

Clear away deposits with high-volume flow and directional coverage in any orientation.

Quick-change 1″ nozzle delivers high-flow output for moving heavy product faster

Top-entry positioning hits solids from above to accelerate breakdown

Designed to move high volumes of liquid and loosened debris

Multi-Orientation Tool

Precision cleaning from above (or any angle) for the toughest tank zones.

Target strategic spots under a floating roof for sludge removal other tools can’t reach

Recovers valuable product by breaking up sludge for circulation and extraction

Reduces product remaining in hard to reach places

Adaptable Mounting

Versatile deployment for various assets.

Fits standard 4″ 150# flange

Adapatable to larger flange sizes using bolt-on adapter plates

Engineered for quick setup and redeployment

No Man Entry Cleaning

Clean from a distance, no confined space entry or manual effort required.

Eliminate confined space and operate remotely through manways or nozzles

Improve crew safety by staying clear of hazardous zones

Speed up cleaning cycles across vessels, railcars, and floating-roof tanks.

Automated Control

Automated industrial cleaning with pinpoint accuracy, all from the safety of a control station.

Define cleaning patterns to match tank geometry, nozzle size, and debris zones

Target solids from multiple angles for complete coverage

Operate via Overseer 3D (full PC software) or Overseer Mobile (tablet or phone)

Effective Applications

- Bullets

- Free Water Knockout (FWKO) Vessels

- Railcars

- Separators

- Top-Down Cleaning with Roof Legs

- Treaters

Technical Specifications

Key Capabilities:

- Power Supply: 120~240 VAC, 50/60 Hz, single-phase

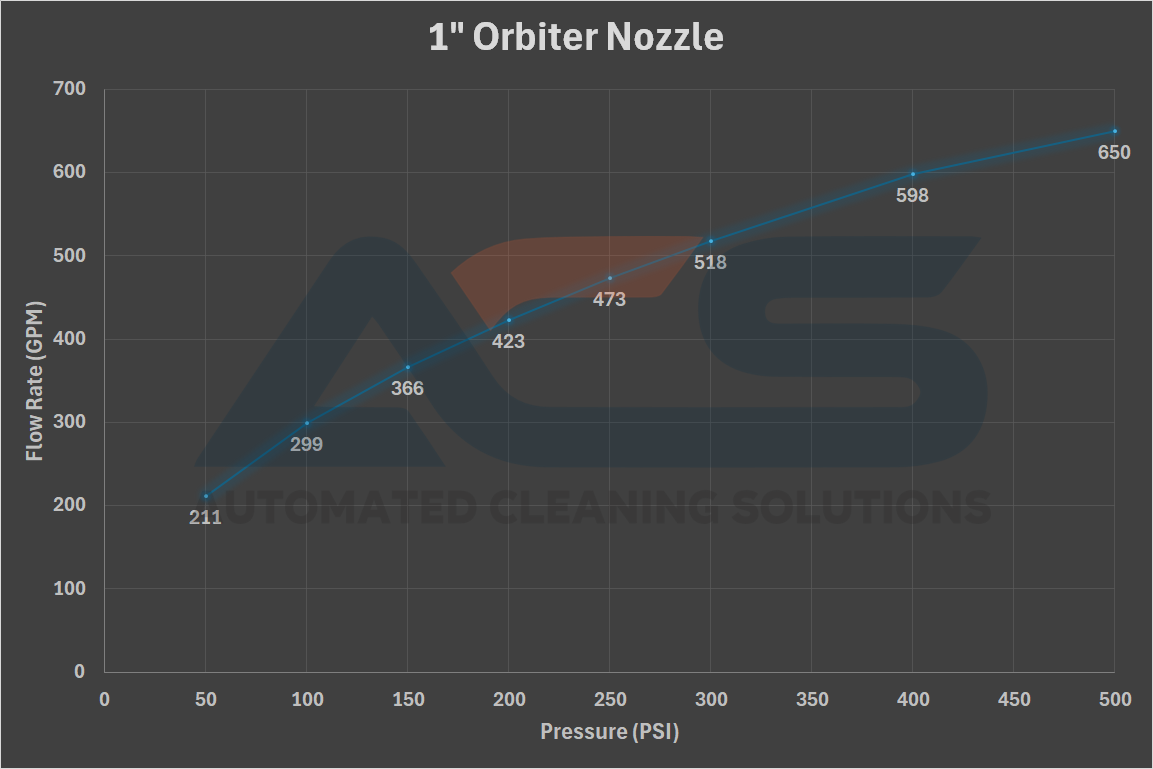

- Maximum Flowrate: 650 GPM

- Maximum Working Pressure: 10,000 psi

- Material Build: 300-series stainless, chemical resistant polyurethane paint

- Water Jet: Minimal turbulence for laminar flow

- Mobility: 360° rotation and up to 70° tilt

- Control: All-electric remote control

- Mounting: 4″ 150# flange

- Software Integration: Overseer 3D and Overseer Mobile

Compliance & Safety:

Hazardous Location Ratings:

- North America (NEC/CEC)

Class I, Division 1, Groups A, B, C & D (without camera & light)

Class I, Division 1, Groups C & D (with camera & light)

Class II, Division 1, Groups E, F & G - International (ATEX/IECEx)

Zone 0/20 compliant (without camera & light)

Zone 1/21 compliant (with camera & light)

Explosion Protection:

– Gas Group IIA & IIB

– Dust Groups IIIA / IIIB / IIIC

– Equipment Protection Level (EPL): Ga/Da

Flowrate Charts

Each nozzle option is designed for optimal performance across various tank sizes and contamination levels. Charts display real-world flow profiles at various pressure levels.