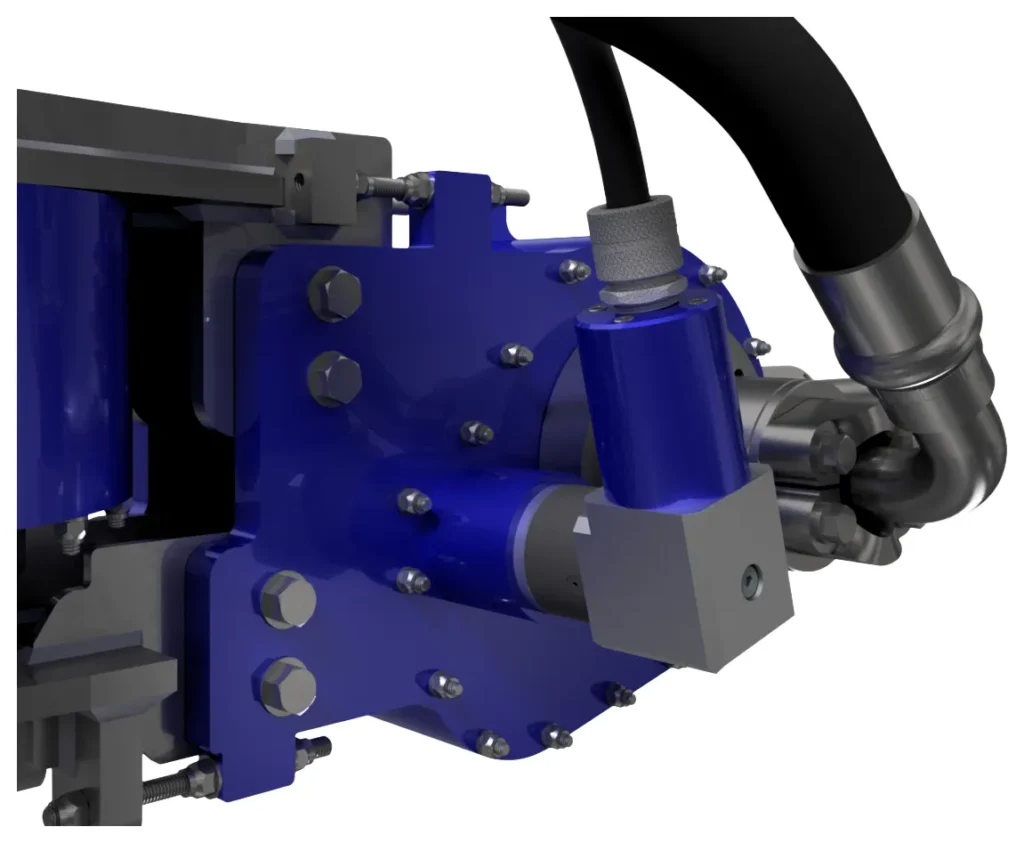

The Eliminator™: High-Impact Water Cannon

Debulking operations in industrial tank cleaning just got a whole lot easier with up to 5,000 psi of blasting power.

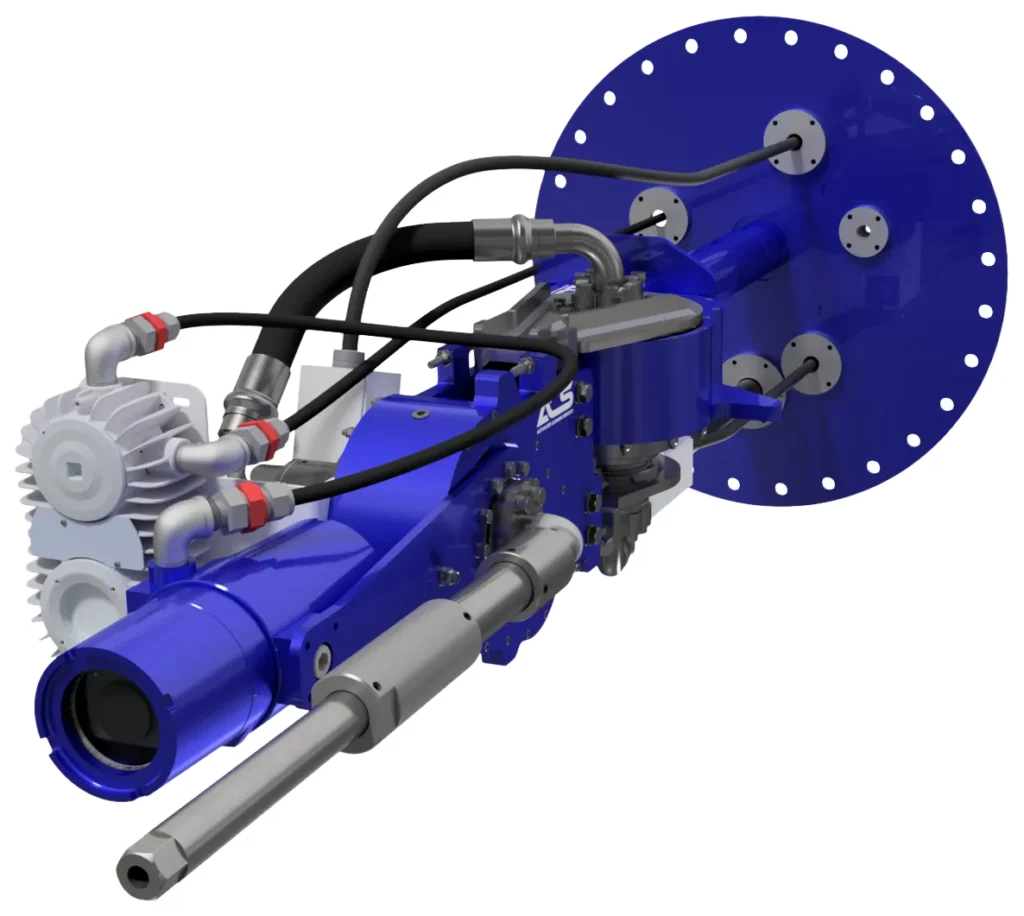

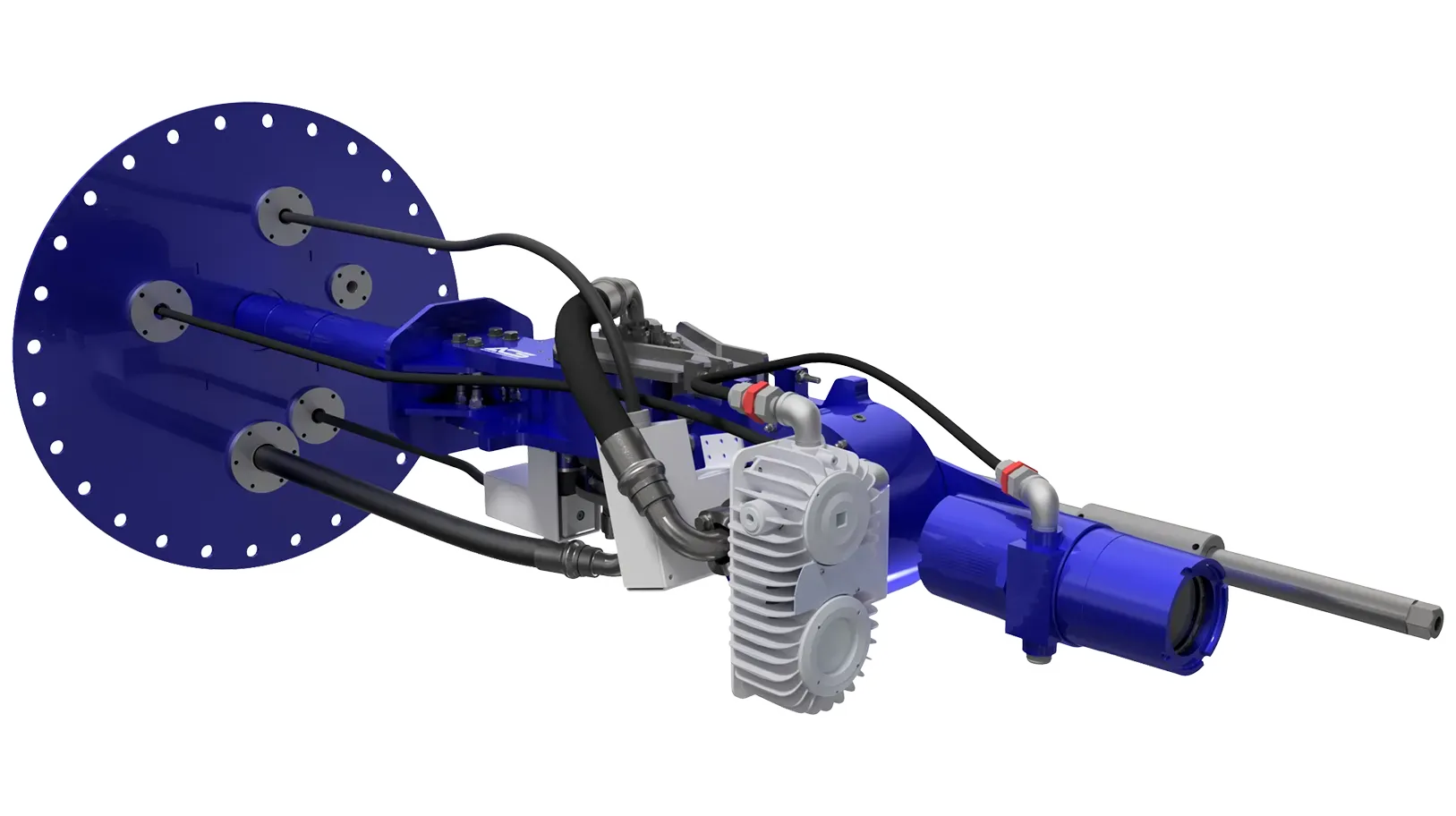

Meet the Eliminator: a fully electric, automated robotic water cannon engineered to blast through heavy solids with extreme force.

Overview

Effective Illumination for Tanks and Vessels

– Bright, glare-free LED lighting for hazardous spaces

– Frosted lens for clear visibility

– Copper-free and built to withstand extreme conditions

21x Optical Zoom Camera

– Crystal-clear visuals from a safe distance

– Built for harsh, industrial environments

– Enables remote inspection and monitoring

Adaptable Mounting

– Supports multiple mounting configurations

– Fast, secure setup

– Engineered for tanks, vessels, and open-top applications.

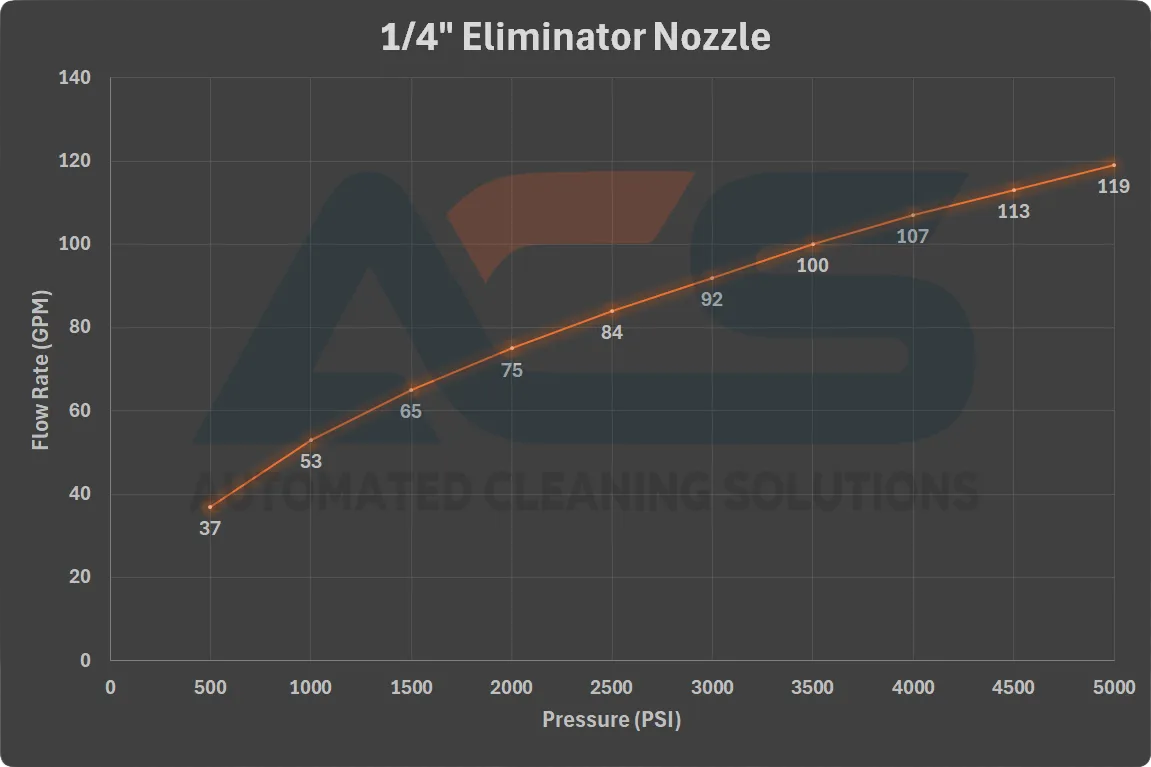

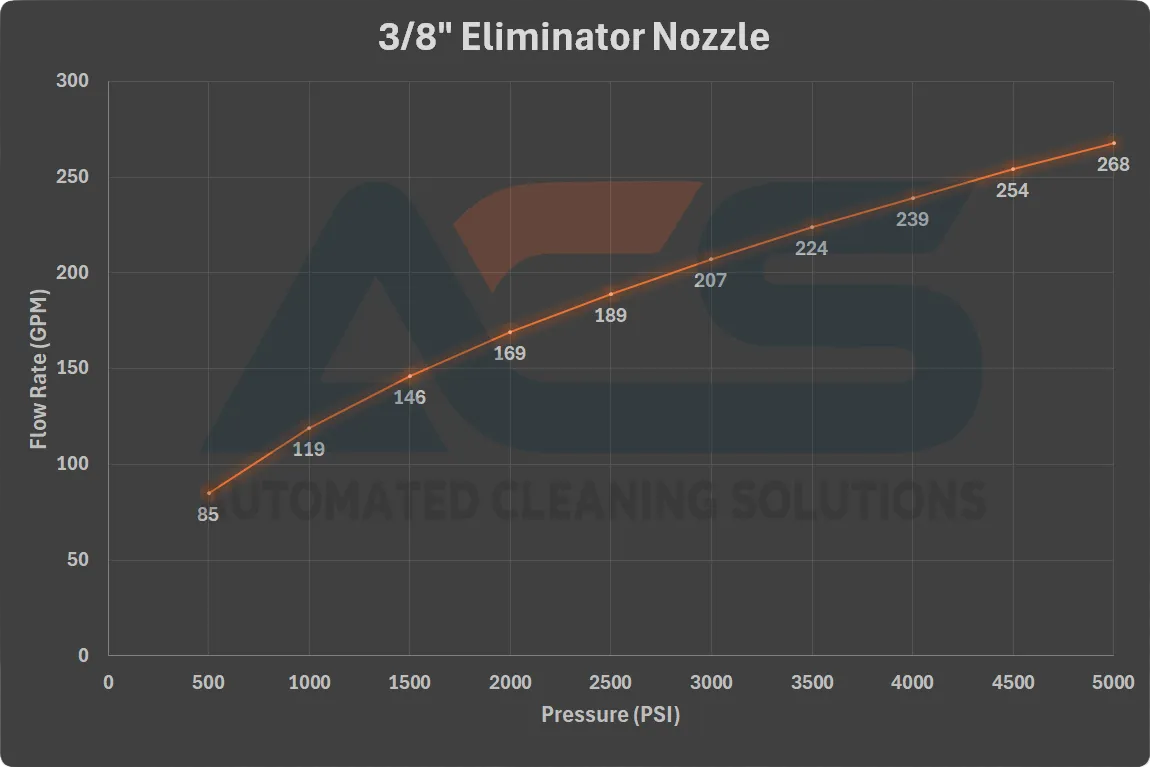

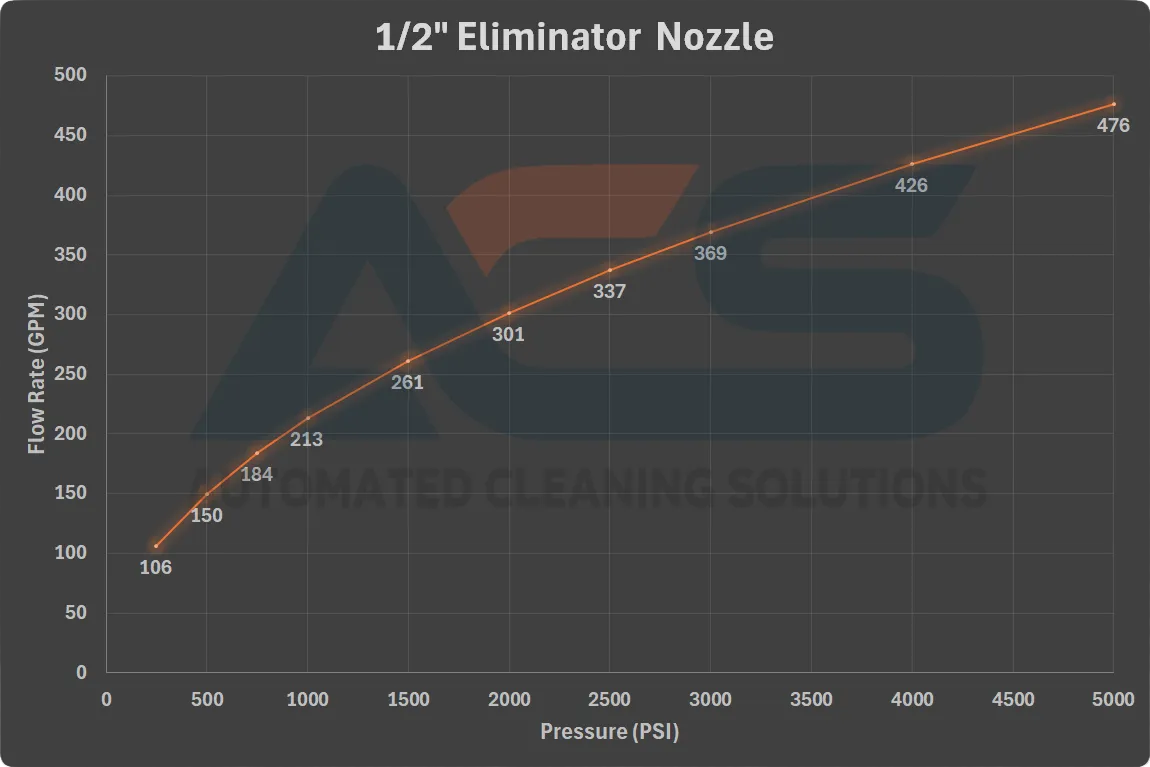

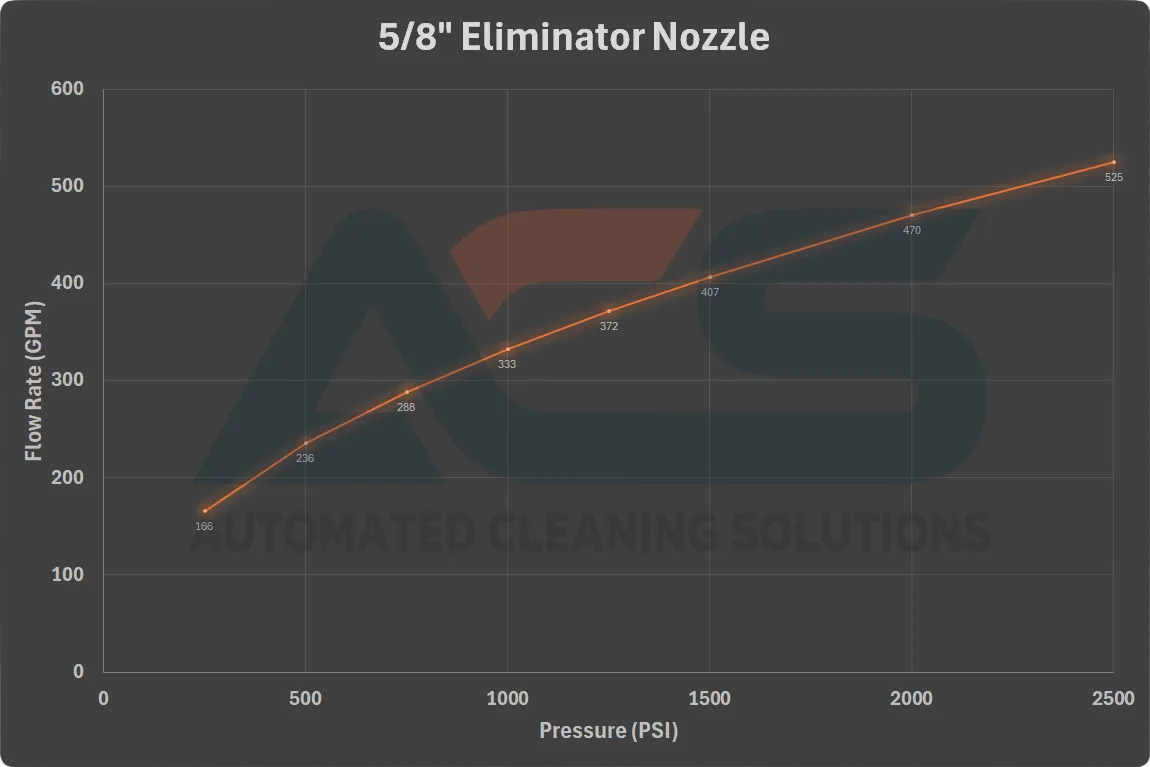

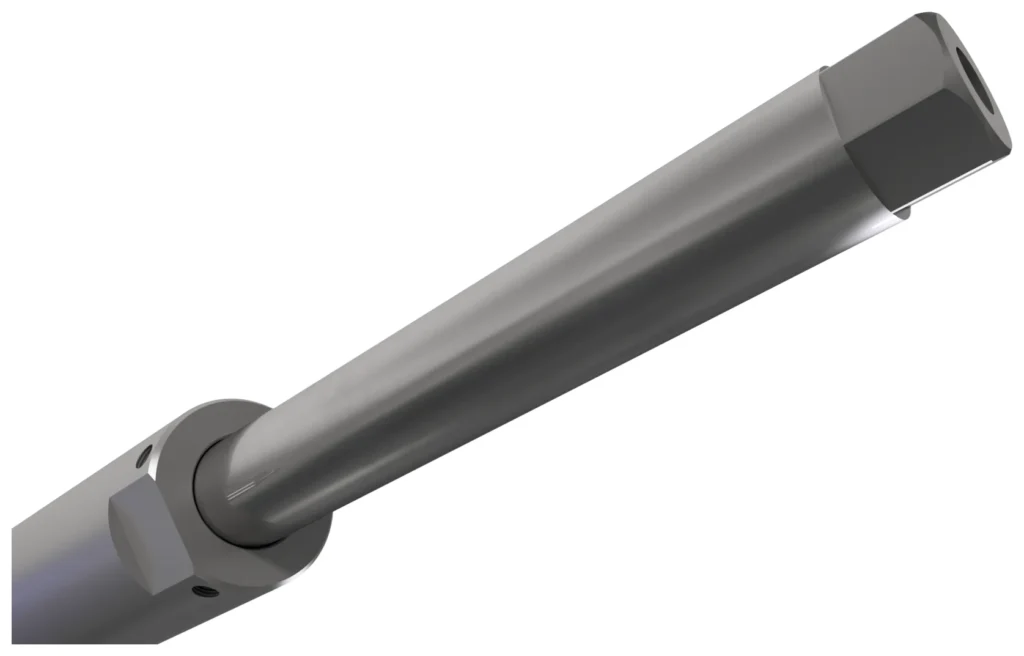

Quick-Change Nozzles

– ¼”, ⅜”, ½”, ⅝” options

– Up to 5,000 psi cleaning power

– Optimize pressure & flow for each job

Features & Benefits

All-Electric Performance

Powered by a standard 120~240VAC electrical circuit. No hydraulics.

Instant, precise, lag-free motion

Adjustable speed from 0.1°/s (ultra-slow) to 10°/s (ultra-fast)

No hydraulic motor or hoses required

High Pressure Impact

Blast through heavy buildup with up to 5,000 psi of high-impact water force.

Eliminates thick sludge and solids for easy slurry removal

Quick-change ¼”, ⅜”, ½”, ⅝” nozzles for different jobs

Dial in pressure and flow for optimal cleaning on any job.

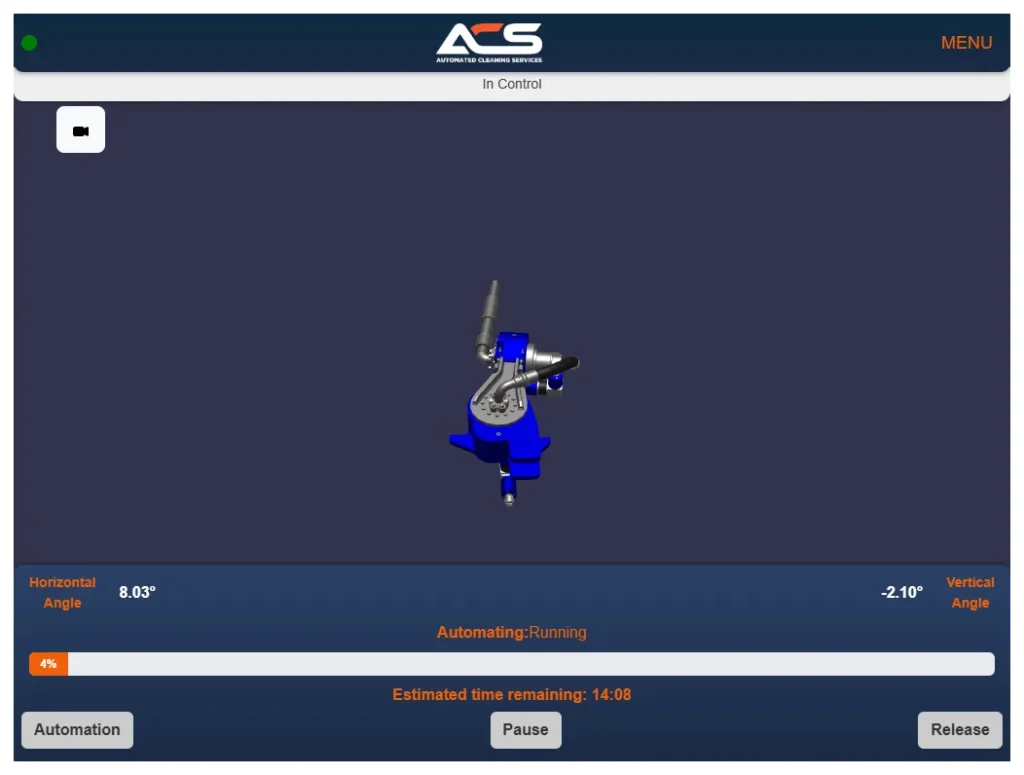

Automated Control

Automated industrial cleaning with pinpoint accuracy, all from the safety of a control station.

Define cleaning patterns to match tank geometry, nozzle size, and debris zones

Target solids from multiple angles for complete coverage

Operate via Overseer 3D (full PC software) or Overseer Mobile (tablet or phone)

No-Man Entry Cleaning

Keep personnel out of hazardous tanks, and let The Eliminator do the dirty work.

No confined space access required, operate from outside the tank

Improve crew safety by limiting exposure to hazardous conditions

Speed through cleaning and get tanks back online sooner

Visual Monitoring

See and record the cleaning process in real-time, from a safe distance.

See everything inside a tank, and zoom in on the details with our 21x optical zoom camera

Live monitoring to confirm tool position, movement, and debulking progress

Capture footage for QA, documentation, or customer reporting

Adaptable Mounting

Flexible deployment across open and enclosed tanks and vessels.

Fits multiple entry points, such as manways, scaffolding systems, door sheets

Configurable for your site layout

Engineered for quick setup and redeployment

Effective Applications

- Bioreactors (Industrial & Municipal)

- Boiler Feed Tanks

- Chemical Processing Vessels

- Clarifiers

- Crude Oil Storage Tanks

- De-Oiling Tanks

- Diesel Storage Tanks

- Digester Tanks (Wastewater & Anaerobic)

- Dilbit Tanks

- Diluent Tanks

- Free Water Knockout (FWKO) Vessels

- Frac Tanks

- Open-Top Settling Tanks

- Separators

- Skim Tanks

- Sludge Holding Tanks

- Slop Tanks

- Spheres and Bullets

- Tanker Trailers and Railcars

- Thickener Tanks

- Treaters

- Waste Oil and Slurry Tanks

Technical Specifications

Key Capabilities:

- Power Supply: 120~240VAC, 50/60 Hz, single-phase

- Maximum Working Pressure: Up to 5,000 psi

- Material Build: 300-series stainless, chemical resistant polyurethane paint

- Water Jet: Minimal turbulence for laminar flow

- Camera System: 21x Optical Zoom HD Camera

- Lighting System: High-intensity LED, 5,000K bright white

- Mobility: 180° movement on dual-axis platform

- Control: All-electric remote control

- Mounting Options: Manways, Scaffolding, Custom Brackets

- Software Integration: Overseer 3D and Overseer Mobile

Compliance & Safety:

Hazardous Location Ratings:

- North America (NEC/CEC)

Class I, Division 1, Groups A, B, C & D (without camera & light)

Class I, Division 1, Groups C & D (with camera & light)

Class II, Division 1, Groups E, F & G - International (ATEX/IECEx)

Zone 0/20 compliant (without camera & light)

Zone 1/21 compliant (with camera & light)

Explosion Protection:

– Gas Group IIA & IIB

– Dust Groups IIIA / IIIB / IIIC

– Equipment Protection Level (EPL): Ga/Da

Flowrate Charts

Each nozzle option is designed for optimal performance across various tank sizes and contamination levels. Charts display real-world flow profiles at various pressure levels.

Dimensions