The Cyclone™: High-Flow Circulation Tank Sweep

Rapidly suspend heavy solids, blend in cutter stock, and homogenize tank contents with up to 100 feet of high-velocity injection.

The Cyclone is a fully electric, automated tank sweep engineered for industrial tank circulation. Available in two models: The Cyclone @ 1,500 GPM and The Cyclone XL @ 6,000 GPM.

Overview

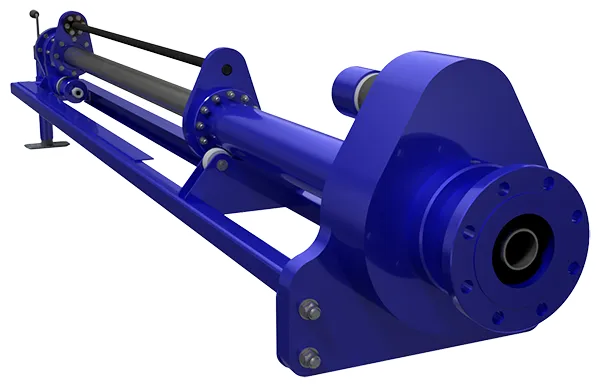

Injection Stinger

– Injects pipe up to 30″ from injection flange to stinger flex point

Laminar Flow Path

– Adjustable tilt up to 70°

– Real-time directional control

Pan Movement

– Enables complete circulation within a tank

– Stinger pan movement is limited to the lower hemisphere (180°) to prevent upward spray

High-Flow Circulation

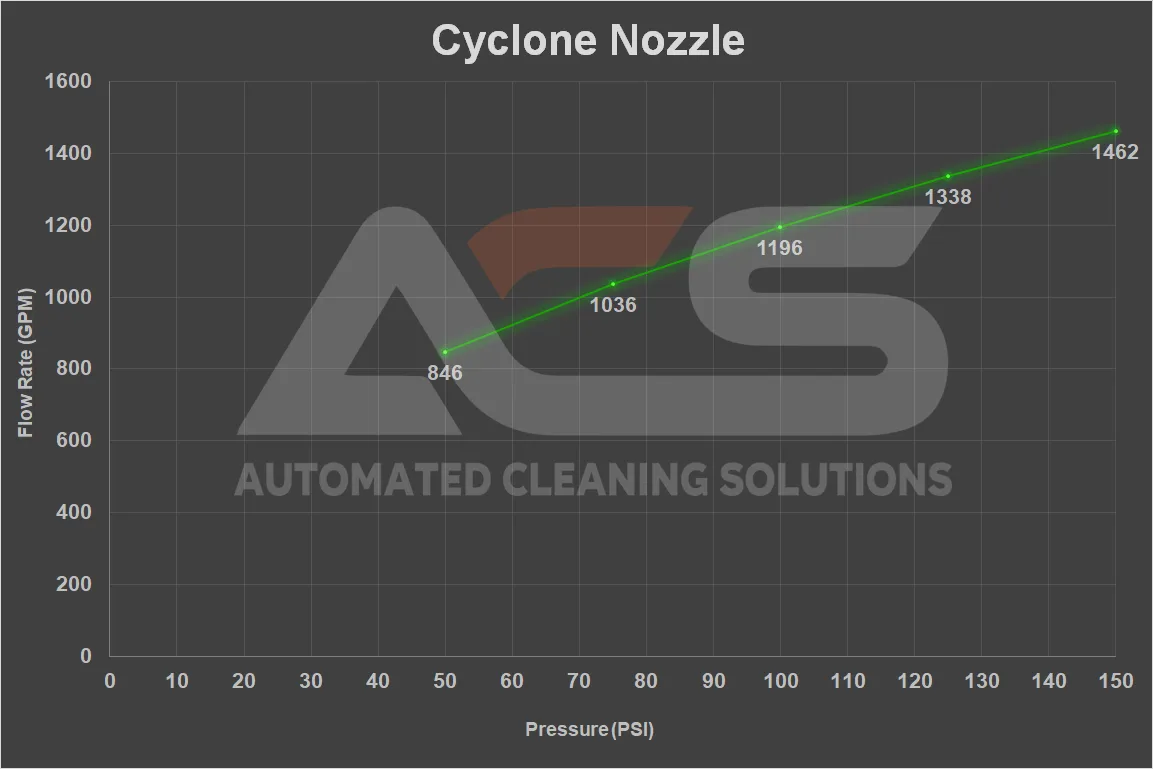

– Cyclone @ 1,500GPM, 2″ nozzle

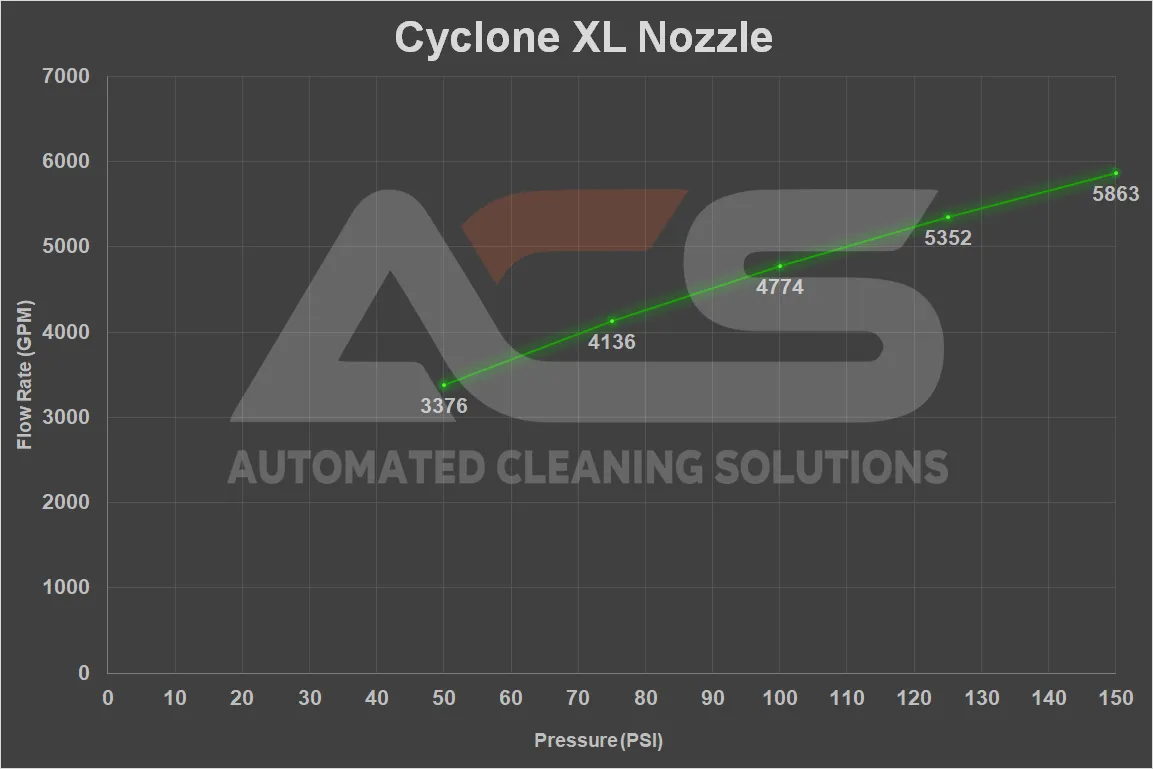

– Cyclone XL @ 6,000GPM, 4″ nozzle

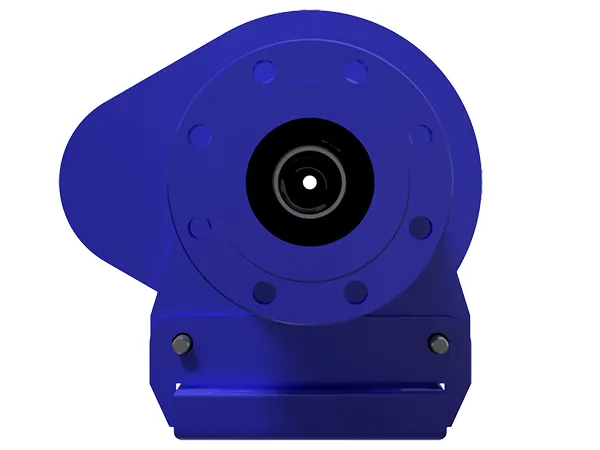

Flange Mounting Options

– Cyclone: 4″ 150# Flange

– Cyclone XL: 6″ 150# Flange

Features & Benefits

All-Electric Performance

Powered by a standard 120~240VAC electrical circuit. No hydraulics.

Smooth, lag-free sweep control with precise electric actuation

Adjustable rotation speed and angle to tailor flow direction

Fully electric. No hydraulic leaks. No mess.

High-Flow Circulation

Two models: The Cyclone (1,500 GPM) and The Cyclone XL (6,000 GPM) deliver powerful flow for tank homogenization.

Suspend sludge and solids for effective circulation

Cut through dense product with up to 100 feet of injection power

Built for extreme-duty industrial cleaning applications

Targeted Circulation

Direct flow exactly where it’s needed to maximize suspension and cleaning impact.

70° tilt and 180° pan movement gives precise control to reach buildup zones and tank edges

Real-time directional control

Reduce dead zones, speed up cleaning and cut down on debulking time

No-Man Entry Circulation

Keep crews out of hazardous tanks while The Cyclone handles high-flow circulation.

No confined space access required, operate externally

Protect crews by minimizing exposure to dangerous tank conditions

Circulate and suspend faster to prep tanks for quicker cleanout

Automated Control

Optimize circulation with precision control from a remote station using Overseer 3D or Overseer Mobile.

Program sweep paths to match tank layout and flow zones

Coordinate multiple Cyclones for full tank coverage

Monitor pressure, flow, and temperature in real-time

Effective Applications

- Bitumen Processing Tanks

- Crude Oil Storage Tanks

- De-Oil Tanks

- Diesel Tanks

- Diluent Tanks

- Dilbit Tanks

- Separation Tanks

- Skim Tanks

- Slop Tanks

Ideal for midstream and downstream operations where heavy solids must be suspended for effective removal.

Technical Specifications

Key Capabilities:

- Power Supply: 120~240 VAC, 50/60Hz, single-phase

- Maximum Flowrate: Cyclone (1,500 GPM) & Cyclone XL (6,000 GPM)

- Maximum Working Pressure: 150 psi

- Material Build: 300-series stainless, chemical resistant polyurethane paint

- Water Jet: Minimal turbulence for laminar flow

- Mobility: 180° rotation and up to 70° tilt

- Control: All-electric remote control

- Mounting Options: 4″ 150# and 6″ 150# flange

- Software Integration: Overseer 3D and Overseer Mobile

Compliance & Safety:

Hazardous Location Ratings:

- North America (NEC/CEC)

Class I, Division 1, Groups A, B, C & D

Class II, Division 1, Groups E, F & G - International (ATEX/IECEx)

Zone 0/20 compliant

Explosion Protection:

– Gas Group IIA / IIB / IIC

– Dust Groups IIIA / IIIB / IIIC

– Equipment Protection Level (EPL): Ga/Da

Flowrate Charts

Each nozzle option is designed for optimal performance across various tank sizes and contamination levels. Charts display real-world flow profiles at various pressure levels.